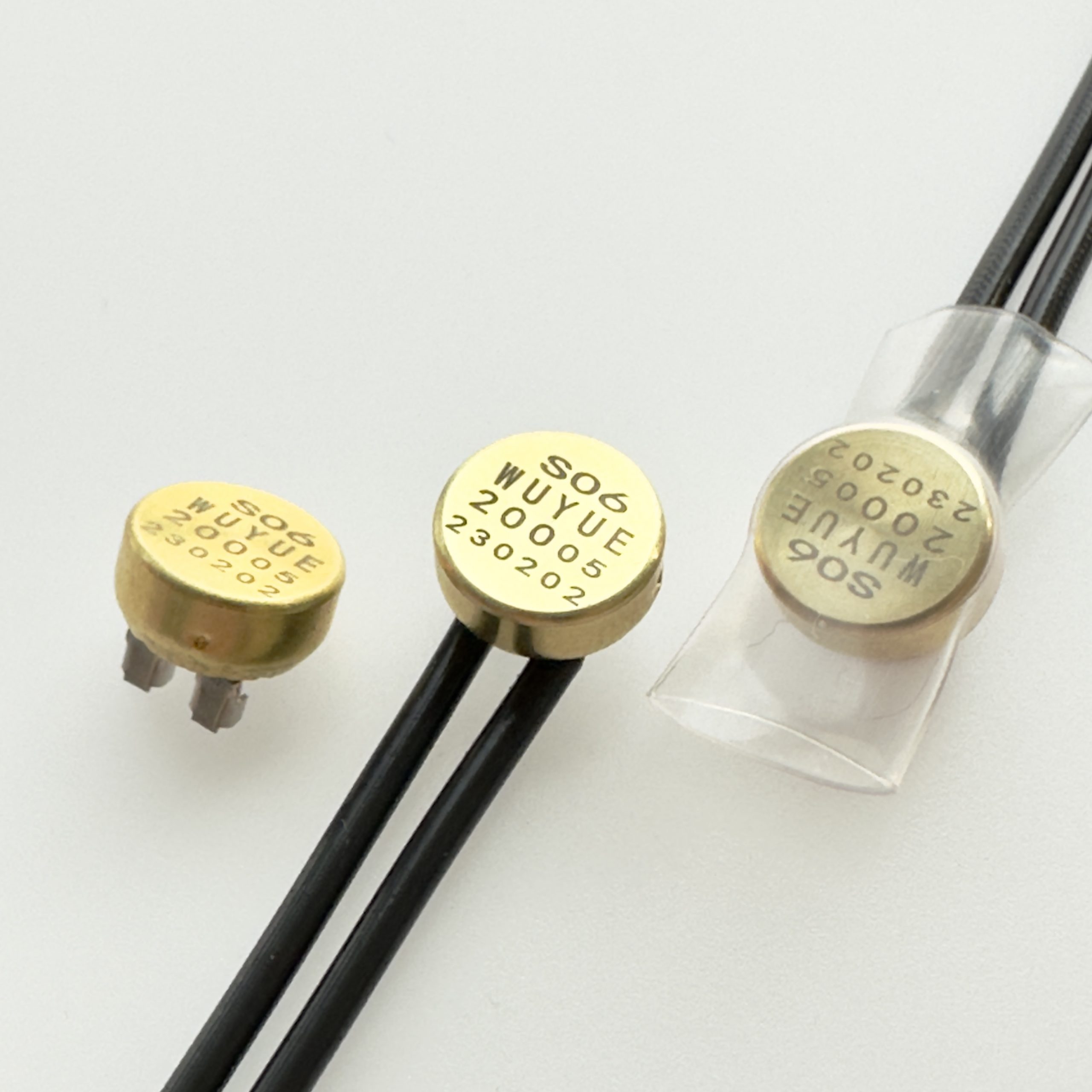

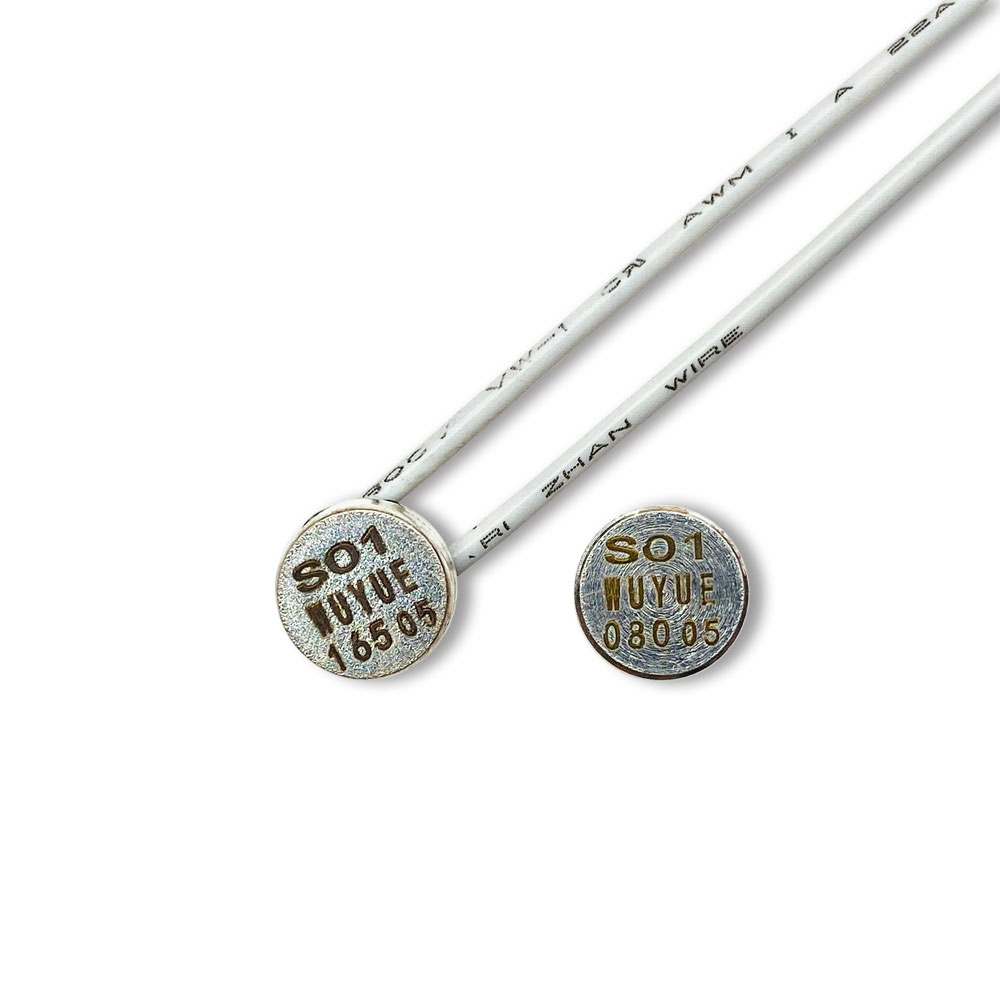

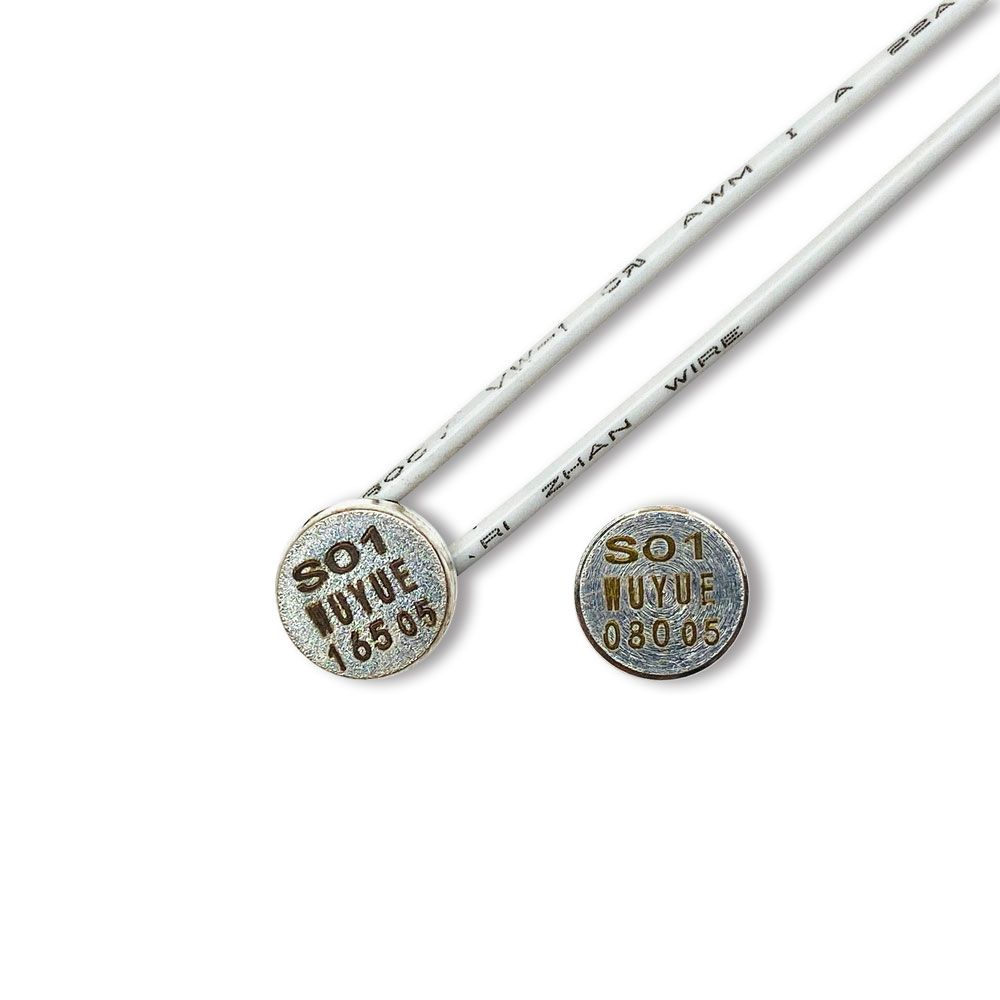

The temperature switch detects the working current, voltage, and temperature of the motor. When the working current or voltage of the motor exceeds the rated current, the corresponding multiple of the voltage, or the safe temperature, when the load becomes larger, the machine will malfunction and the motor will stop heating directly. Burn out the motor. At this time, the temperature switch can act and the motor stops working. So which part of the thermal protector discharge machine is the most effective for detecting temperature?

Generally, the temperature switch is installed in the motor at a position close to the winding, which is relatively effective. The two power cables of the temperature switch are connected to the incoming wire of the motor to directly sense the temperature of the winding. When the temperature is about to exceed the limit, the temperature control switch is cut off. The contactor coil loop makes the motor cut off. The DC motor needs to be placed in the winding above the motor. The protection effect of this kind of temperature switch is far better than that of thermal relays. It is widely used in foreign countries. Nowadays, the domestic use is gradually increasing. More and more motor manufacturers are beginning to use temperature switches for protection. Switch products gradually replace foreign imported products.