The tubular electric heating is added with a temperature switch to realize automatic temperature control, which is safer and more reliable. Put an alloy resistance wire in the metal tube as a heating element, and then connect the heating element in series with a temperature switch to effectively realize the tubular electric heating overheat protection function.

Tubular electric heating is mainly composed of metal shell, resistance wire heating element, crystalline magnesium oxide powder, insulating ceramic body, power cord, wiring device, etc. The working principle is that when the tubular electric heating is heating water or other liquids, when the heated liquid reaches the temperature set by the temperature switch, the temperature switch will automatically disconnect the circuit and the heater will stop working. When the temperature drops to the set temperature, the temperature switch turns on the circuit and the heater restarts, which plays a protective role.

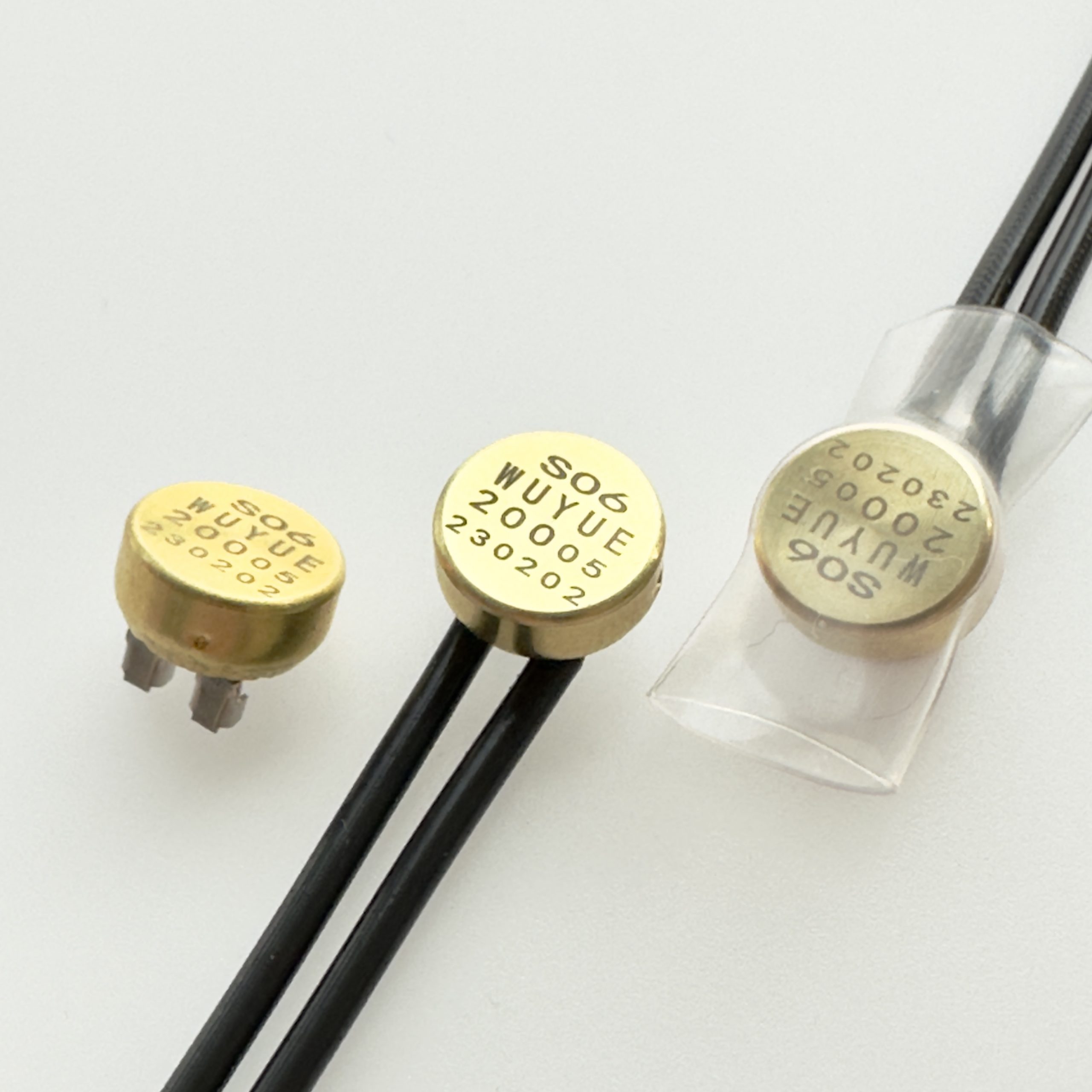

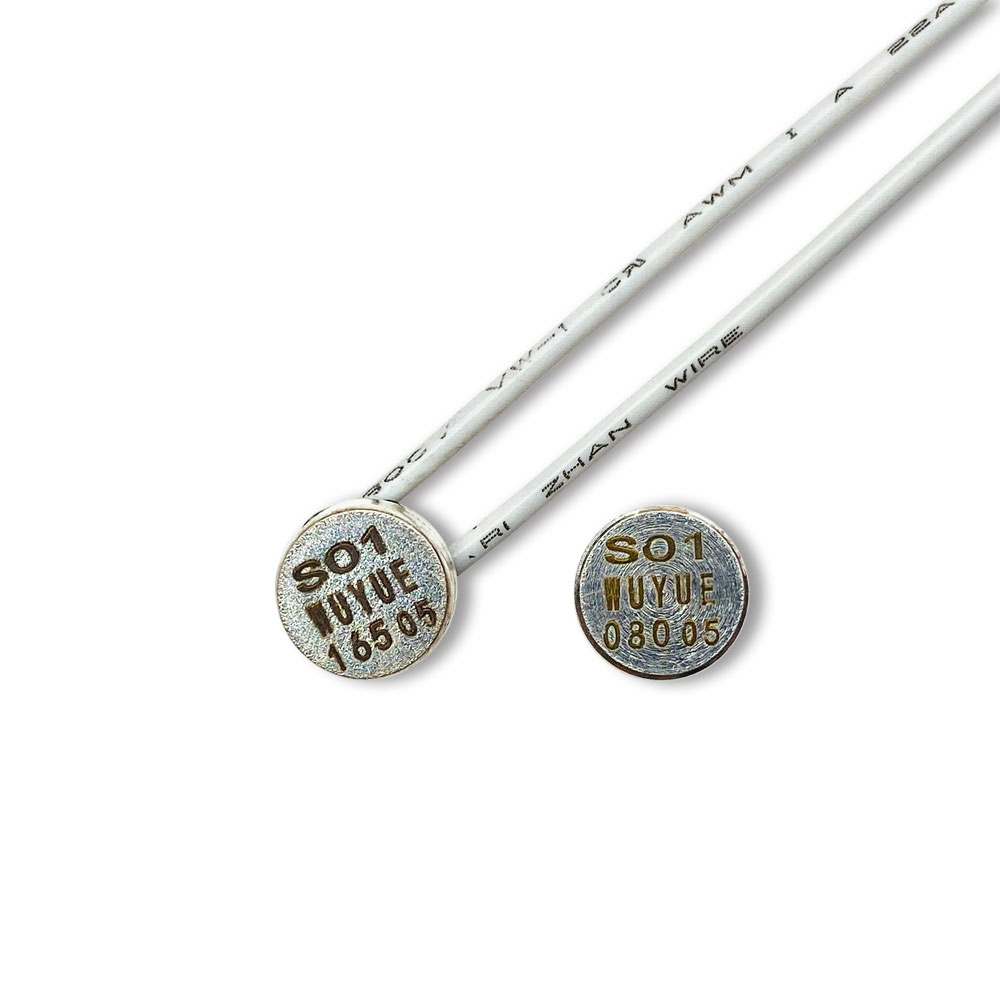

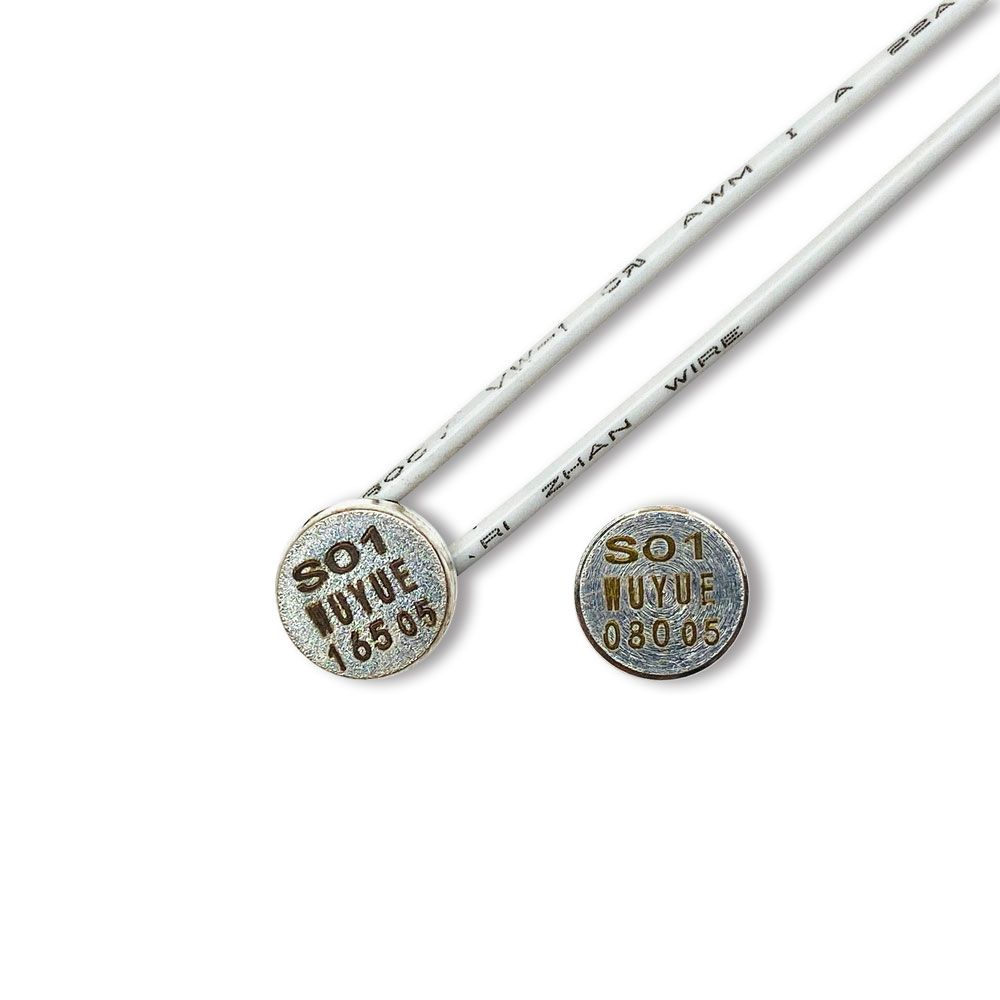

The temperature switch of the tubular electric heating tube generally adopts a small size model, which is easy to install in the tube.